From "noble metal" to bathroom darling: The past, present, and renewed value of space aluminum showerheads

Release time:

2025-07-28

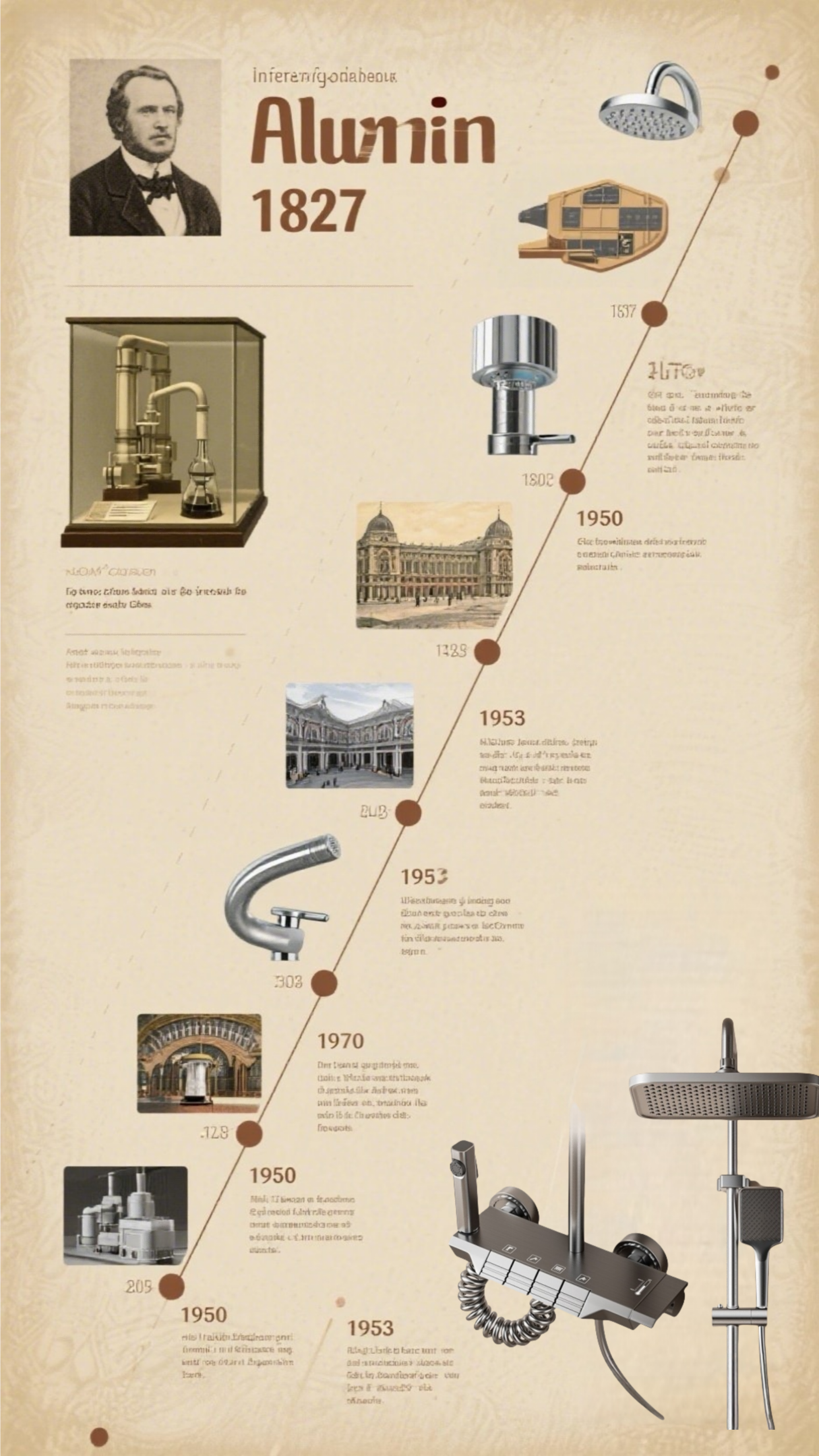

Aluminum's "Past Life"

Early understanding and initial utilization: In ancient times, although people did not understand aluminum metal itself, they had begun to utilize aluminum compounds. For example, ancient Egyptians used alum as a dye fixative, ancient Romans used it to purify water and treat wounds, and ancient China used it for water purification, soap making, and medicine. In 1807, British chemist Humphry Davy first proposed the existence of "aluminum." In 1825, Danish scientist Hans Christian Ørsted first obtained a small amount of impure aluminum metal through electrolysis. In 1827, German chemist Friedrich Wöhler obtained purer aluminum powder by reducing anhydrous aluminum chloride with potassium metal, and people's understanding of aluminum gradually deepened.

Expensive "noble metal": Before aluminum extraction technology matured, due to its complex preparation process and reliance on rare metals such as potassium and sodium for reduction, aluminum production was extremely low and its price was expensive, making it a "noble metal" at the time. At the 1855 Paris World Exposition, aluminum ingots were displayed alongside diamonds and jewelry; at a banquet, Napoleon III only provided aluminum tableware to honored guests; in 1884, the "cap" at the top of the Washington Monument in the United States was made of pure aluminum. These all reflect the rarity and preciousness of aluminum at that time.

Aluminum's "Present Life"

Industrial production brings about change: In 1886, Charles Martin Hall of the United States and Paul Héroult of France almost simultaneously invented the electrolytic method for extracting aluminum, the "Hall-Héroult process." This technology dissolves alumina in molten cryolite for electrolysis, greatly reducing the production cost of aluminum, making large-scale industrial production of aluminum possible, and significantly lowering the price of aluminum. It transformed from a "precious metal" into a widely used industrial metal, laying the foundation for its large-scale application in various fields.

Widely used in various fields: Aluminum has excellent properties such as lightweight, corrosion resistance, good conductivity, and easy processing, making it widely used in many fields. In the industrial and transportation fields, and in aerospace, from the Wright brothers' first airplane to the modern Boeing 787, aluminum alloy accounts for more than 50% of the airframe weight; in the automotive industry, both traditional and new energy vehicles use a large amount of aluminum to reduce weight and improve performance; in rail transit, high-speed rail bodies and subway cars also use a large amount of aluminum alloy. In the construction and packaging fields, aluminum alloy doors and windows, curtain walls, and high-voltage cables are widely used in construction; in the packaging field, aluminum foil is used for food and drug packaging, and aluminum alloy pull tabs are also widely used. In the electronics and new energy fields, aluminum is indispensable for mobile phone and computer casings, electric vehicle battery casings and motor casings, photovoltaic power station supports, and energy storage device casings.

Space Aluminum Shower Head - A New Application of Aluminum in the Bathroom Field

Characteristics of space aluminum: Space aluminum is an aluminum-magnesium alloy that has undergone special treatment such as high-temperature oxidation. Its main component is aluminum oxide. It has high strength, good corrosion resistance, lightweight and durability, and can withstand temperatures of several thousand degrees and strong impact forces. Due to the surface oxidation treatment, the thickness of the oxide film reaches 10-25μm, making it resistant to humid and acidic and alkaline environments, not easy to rust or fade, and environmentally friendly. Its oxidation resistance is even better than stainless steel, and it also has good machinability. It can be formed by die casting and extrusion, making it suitable for making complex-shaped metal parts.

Related News